Epoxy Coating

From the time the stone is extracted from the mine to the time of production of building stones, processes must be carried out on the stone. The operation that is performed on the cup stone in order to fill its cracks and grooves in order to increase the strength of the raw stones before processing them is called epoxy agitating.

It is better for the existing stone cups to have characteristics, the most important of which is the size of the stone cup.

In order for a stone to have less waste and debris, it is very necessary not to have fractures in the corners of the stone cup.

To perform this operation, they first start extracting the stone from the mine with various devices such as stone crushers and other cases.

After extraction, the stones are taken to the scale, and after determining the weight of the stone, the stone is brought to the factory and the processing steps are carried out on them.

Before the coupe enters the processing stage, measures are taken to strengthen it for cutting.

First step:

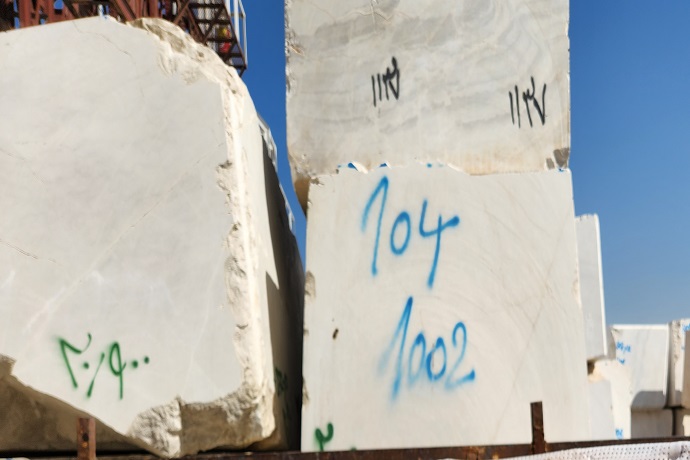

After extracting the raw stones from the mine, they are taken to the quarrying factories.Some cope stones have regular and cubic shapes, while cope stones with irregular shapes that cannot be cut with a saw are cut with a peak, which is called the so-called process of folding the cope stone.

Coop stone extracted from the mine

Second stage:

The process of epoxy aginization (vacuum) of cope stone is done after crushing it.

The steps of epoxy agitation are as follows:

The surface of the stone is washed with a car wash and completely dried.

The temperature of the stone reaches an acceptable level in an enclosed room or open space, under the sun.

A net with plastic is stretched around the cup stone.

Pulling netting and plastic around the stone

By means of the suction pump, a vacuum is created inside it.

Creating a vacuum by means of a suction pump

On the other hand, epoxy is injected into the plastic attached to the stone.

The injected epoxy is injected into all cracks and veins due to the presence of vacuum.

Epoxy injection

After the injection is completed and at least 48 hours have passed, the desired coupe is ready for cutting.

Finishing the vacuuming of the cup stone

Features of epoxy resin used for epoxy agitating:

High strength

Very low viscosity

Very long gel time

And as a result, very high permeability

Also, the high strength and excellent permeability of this epoxy resin increases the resistance of the stone against chemicals and other destructive factors.

Call +982533340068 for more information and executive services.