Implementation of decorative pieces

Epoxy is a type of thermosetting polymer (thermoset) that is made up of two main components: epoxy resin and hardeners, known as hardeners. Epoxy resin has various applications in industry. Epoxy is in a liquid state and hardens during the curing process (using its appropriate hardener).Epoxy resin is mostly used for molding. Due to the formability of epoxy resin, this material easily takes the shape of the mold and has great strength after forming.

Molding using epoxy resin to make jewelry

Epoxy resin is suitable for both mold making and is an option for making jewelry. Epoxy jewelry comes in a variety of designs and colors, and can be made into almost any shape or design.

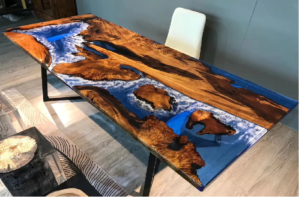

Molding and making an epoxy table

You can use epoxy resin to create beautiful 3D designs on your tables, and you can also use epoxy resin in combination with wood to make wood.

Types of molds suitable for epoxy

Plastic molds: These molds can be used to make decorative and ornamental products.

Silicone mold: Silicone molds are soft and flexible, and you can make these molds yourself, giving you more freedom to design the epoxy.

Latex mold: Latex molds are as soft as silicone molds and have a wide variety of designs and shapes that can be used to mold jewelry.

Features of epoxy molding:

Epoxy resin for molding does not change shape or size after using the mold

High mechanical strength

It has the ability to accurately copy the part.

Epoxy resins require a release agent for molding and removal from the mold, which is available in the form of wax and spray on the market, but it must be used carefully in the mold. You can use wide adhesives to remove epoxy from the mold, which are less troublesome to remove epoxy from the mold, because this material is sensitive to fat and becomes opaque in the presence of wax and spray, which are oily. Of course, if applied correctly, these release agents will also be suitable.

Methods for removing bubbles from epoxy resin:

Seeing bubbles is troublesome and undesirable for resin workers, so we recommend the following methods for removing bubbles:

-Choose the most suitable epoxy resin for your job.

– Mold the resin hot.

– Heat the epoxy resin before molding.

– The temperature of the resin should be close to the surface temperature.

– Before filling all the parts with resin, swirl some resin over the entire surface.

– First, dip the items you plan to put into the mold into the epoxy resin.

– Once you have poured your epoxy resin, use a flame to remove bubbles.

– Control the humidity of the application environment.

– Use a vacuum to remove bubbles from the epoxy.